Future-proof assembly concept for high-end shavers

The high-tech shavers made by Philips are in great demand and considered premium products all over the world. Unlike most razors produced, these are assembled in Drachten, Netherlands and not in the Far East. Learn how 200 robots embedded into a groundbreaking assembly concept deliver upon the requirements of quality, profitability, and flexibility.

Production of shavers is under an immense cost pressure and the trade offer for the devices is quite large. In combination with factors like quality and design, the purchase decision is also affected by the price. To remain competitive under these conditions, Philips’ shaver production operates out of two production sites: one in China and the other in Drachten. The Philips center for research and development also resides in Drachten, which means that all new Philips shavers, ranging from the standard model to the high-tech shaver, are developed out of this facility.

The assembly of the high-tech shaving devices demands the highest level of quality, whereas standard shaver models rely on mostly manual labor. This demand for a high-quality assembly process has made the Drachten plant turn to automation for their production. Reliable assembly processes with integrated quality control assure the highest level of quality of the consumer products. For Bremer Werk für Montagesysteme GmbH, it is no secret how to build the necessary equipment for demanding assembly tasks. The specialists had the industry expertise and knowledge, but in the case of Philips, there was much more required than pre-existing, proven solutions off-the-rack.

“The real challenge in finding the right solution for Philips was to accomplish the enormous model variety of the high-end shavers. Currently about 60 different product lines culminate in some 600 single products. Thereby the product spectrum changes almost every day,” said Matthias Schaller, head of robotics at the Bremer Werk für Montagesysteme GmbH. Beyond that obstacle, Philips outlined a requirement for an assembly solution that demanded much more than just the foresight of the construction engineers. In essence, Philips was insisting on a guaranteed future level of performance of their equipment. Sietze Bremer, Senior Sourcing Specialists Industrial at Philips said, “We wanted to implement a future-oriented assembly concept. And with regard to the total investment, we wanted to feel certain that the equipment would still be able to economically produce shavers in ten years without knowing how the shaver of the future will look at all.”

Flexibility was requested continuously.

The solution: flexible components from one source

How does one build machinery capable of assembling products that nobody knows for sure how they will look and work in the future? This presented a significant challenge that would test the ambition and creativity of the Bremen people. It turns out, the solution meant Omron. The automation strategist Schaller explained that, “after first analyses, a system concept emerged, which could only work on the basis of extremely flexible automation components from one source. Due to the multitude of assembly stations, a component mix of different manufacturers would have led to an uncontrollable complexity.

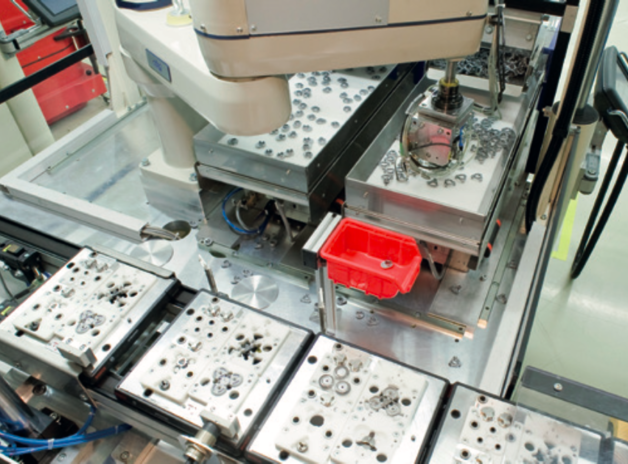

Thus, we needed 6-axis robots, SCARA robots, vision systems, part feeders and controls – and everything from a single source. In this connection we counted on Omron Adept, as their high-duty components meet all requirements and already proved their efficiency in similar projects in the past.

The first item to address was how to achieve the highest levels of flexibility. Maximum flexibility in the automation was delivered in three ways. Firstly, the modular layout of the shavers consists of three main components that can be manufactured independent of one another on different production lines.

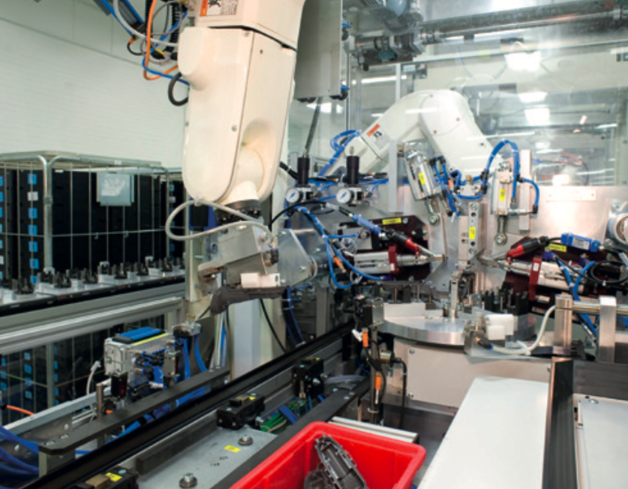

The second important factor is the conception of the complete equipment which is also based on the module idea. In Drachten, the three-head-shavers are currently assembled on a total of thirteen slitting lines each composed of five to eight cells. Each cell operates autonomously and can be connected or disconnected according to the plug & play principle. The concept of smaller and mutually independent lines with autonomous cells does not only mean a flexibility booster but stands also for maximum availability. Because: If it gets stuck at one point, not the entire machine will stop, but only one of the lines.

More than 200 robots and 70 AnyFeeder systems

When the integration of the new lines is complete, more than 200 robots and 70 Anyfeeder systems will provide the frictionless assembly system for the shavers. This sets up the third critical flexibility factor, which was the choice to use Omron products. According to experienced Senior Manager Sietze Bremer, “We count on Omron completely when expanding the equipment. The Viper 6-axis robots s650 and s850 as well as the Cobra SCARA robots s350, s600 and s800 are predominantly equipped with the vision guidance and inspection package, Omron AdeptSight and arrive already having been tried and tested in existing lines. The robots impress with their precision, speed, and availability and perform the tasks with the high accuracy that is required.

Bremer explains that “a key role within the cells relates to the AnyFeeder. Without its approved flexibility, the system concept would not have been feasible. The inherent flexibility of the AnyFeeder systems affected a number of areas throughout the assembly automation process: wherever effi cient assembly with a high-degree of individualization mattered. At the Philips plants, Bremer Werk für Montagesysteme counted on the Omron AnyFeeder SX 240 flexible feeding system. When synchronized with Cobra and Viper robots and AdeptSight vision guidance, the AnyFeeder system redefines what it means to be flexible in small-parts feeding applications.

“Flexible feeding systems are key components for the intelligent assembly automation, especially relating to the sustainability of the Philips equipment,” said Schaller. “Regardless of how the single parts of the shavers will look in the future, the highly-flexible AnyFeeder will feed them as bulk goods. After ‘seeing’ the parts, the robots will pick them up and proceed to assemble the devices. And in ten years, this simple and basic principle will not change."

Vision guidance is mandatory going forward

A majority of the robots on the existing lines were already equipped with vision guidance and all new machines are scheduled to have a vision system. This again reinforces the focus on flexibility: “A robot with integrated vision guidance can be perfectly adopted for varying tasks and, furthermore, can take over additional work contents, for instance in the field of quality control,” said Bremer. The groundbreaking automation solutions guarantee an economic and efficient assembly of high-end shavers. In connection with the innovative components from a single source, the sophisticated assembly concept assures an unrivalled level of sustainability and the Philips plant is now one of the most innovative production sites for high-quality shavers.

source: Omron